MIDDLETOWN, Pa. -- When Anilchandra Attaluri, Penn State Harrisburg assistant professor of mechanical engineering, approached alumnus Tim Ritter, a co-owner of Universal Protective Packaging, about joining in a research project, Ritter was in.

Supported by a grant from the PA Department of Community & Economic Development’s Manufacturing PA Innovation Program, Attaluri’s research focused on preparing Pennsylvania to be a national and international leader in manufacturing. He recommended that small to medium-sized manufacturing businesses find ways to improve existing manufacturing equipment and processes, use data analysis techniques to be able to predict when a piece of equipment will need maintenance, and attract new graduates for the high-paying manufacturing jobs. Attaluri aimed to do this by testing his research on the automated practices of thermoformed protective packaging performed in Ritter’s company.

"It seemed like it would fit pretty well with some of our company objectives of trying to advance our technology,” Ritter said. "We’re a custom thermoform packaging manufacturing company, and we do the whole packaging process from the design of the package to the manufacturing of the molds and the tooling that’s required to make the custom packaging, and then manufacturing the package as well.”

Ritter has been with UPPI for nearly 30 years. He and Attaluri originally met at a networking event on campus and eventually struck up a strong working relationship. The outcome of their research partnership has paid many dividends, not the least of which includes Attaluri’s training the next generation of engineers through hands-on learning.

Brandon Rauenzahn, a recent Penn State Harrisburg graduate in mechanical engineering, is a testament to that success.

Having been introduced to engineering in high school, Rauenzahn said he developed his interest for the profession early on. His passion grew after he started taking courses at Penn State Harrisburg. Then, in the fall of his senior year, Rauenzahn joined Attaluri’s research team.

“I was looking for someone who had really good computer drawing skills and could interact with UPPI,” Attaluri said.

According to Rauenzahn, “I wanted to work on the project because it involved automation and design, two things I was really interested in.”

Rauenzahn’s main role was as a liaison between Attaluri’s lab and UPPI. He did such a good job, that when he graduated in spring of 2021, Ritter hired him as a project engineer.

Ritter acknowledges the “great advantage” of students getting real world experience through research and the competitive edge it provides them in seeking a job.

“One thing we noticed about Brandon was his ease with working hands-on and doing the technical, engineering side of work,” Ritter said, “He was equally adept, and to us, that was a real valuable skill.”

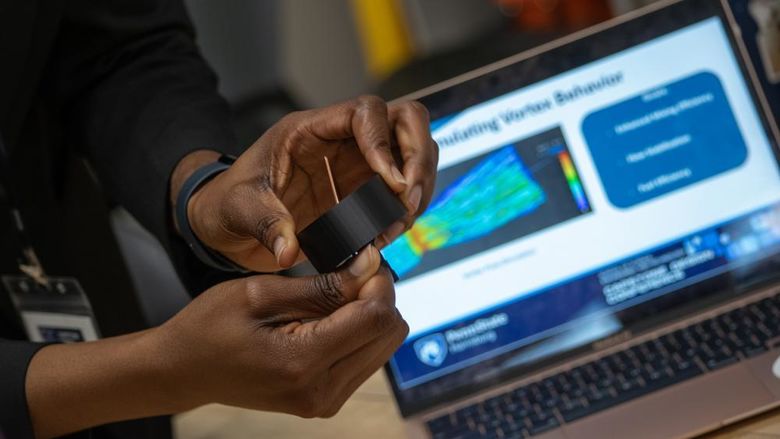

Attaluri’s research project continues with a select group of current Penn State Harrisburg students who have their sights set on developing an on-site laboratory. Their work focuses on collecting data on good and bad sensors and analyzing the data to try to spot potential errors before they happen.

Research collaborations with industry deliver widespread benefits, and Attaluri’s partnership with Ritter and UPPI is a good example. Students gain experience and job opportunities, while companies find solutions to improve business operations and gain access to a specifically trained workforce. These benefits ripple broadly. As Attaluri explains, his research in increasing machine productivity leads to faster production, enabling companies to better meet marketplace demand, and successful businesses in turn hire more employees. All these advantages have a positive impact on the economy overall, he said.